Tesla's high-voltage systems in electric vehicles require specialized knowledge and safety procedures for technicians due to their distinct architecture. Maintaining Tesla high voltage safety is crucial during repairs, addressing hazards like arc flash, electric shock, and fire. Strict adherence to safety protocols, proper training, protective gear, and de-energization of work areas are vital to mitigate risks, ensuring the safety of both employees and customers.

“In the realm of electric vehicle maintenance, Tesla’s high voltage (HV) systems pose unique challenges. This article delves into essential Tesla high voltage safety procedures designed to protect technicians. We explore the intricate HV systems, emphasizing the critical role of proper gear and protocols. Additionally, we outline emergency response strategies and de-energy procedures, ensuring technicians are equipped to navigate potential risks effectively. By adhering to these guidelines, professionals can ensure safe interactions with Tesla’s advanced technology.”

- Understanding Tesla's High Voltage Systems

- Safety Gear and Protocols for Technicians

- Emergency Response and De-energy Procedures

Understanding Tesla's High Voltage Systems

Tesla’s high voltage systems are a cornerstone of their electric vehicles, powering not just the motor but also crucial safety features. Understanding these systems is paramount for technicians working on Tesla vehicles, as they differ significantly from traditional internal combustion engines. These advanced electrical architectures incorporate high-voltage batteries and power electronics, enabling efficient and clean energy delivery to drive and control the vehicle.

Adhering to strict Tesla high voltage safety procedures ensures that technicians work in an environment free from electrical hazards. This involves recognizing potential risks like arc flash, electric shock, and fire, all of which are heightened with high-voltage components. Proper training, protective gear, and adherence to protocols for vehicle disassembly and reassembly are essential when dealing with these systems, especially during collision repair or car dent removal processes at a specialized collision repair center.

Safety Gear and Protocols for Technicians

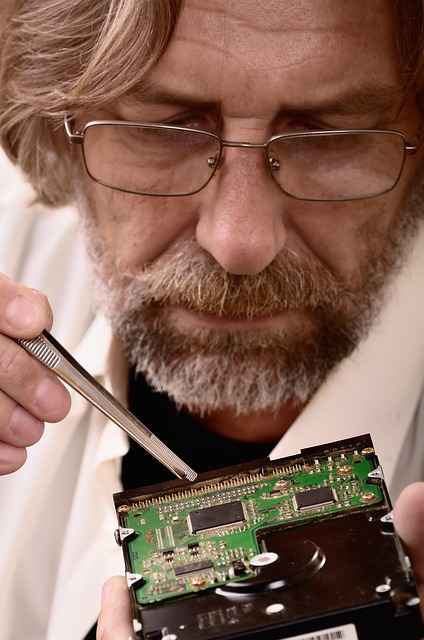

When working on Tesla vehicles, especially those equipped with high voltage (HV) systems, technicians must prioritize safety above all else. This involves donning appropriate Tesla high voltage safety gear, which includes insulated gloves, boots, and protective clothing designed to withstand electrical risks. Eye protection is crucial, as are respirators or masks to prevent exposure to hazardous materials commonly found in automotive body work and collision repair processes.

Adhering to strict protocols is essential for technicians engaging in vehicle repair services on Tesla HV models. This includes ensuring all tools and equipment are properly grounded and using non-conductive materials. Work areas should be de-energized, and clear communication among team members is vital to avoid accidental contact or short circuits. Regular training sessions specific to Tesla high voltage safety procedures are recommended to keep technicians apprised of best practices in this specialized field, ensuring the safety of both workers and customers alike.

Emergency Response and De-energy Procedures

In the event of an emergency, Tesla high voltage safety procedures demand a swift and calculated response. Technicians must be trained to quickly assess the situation and take appropriate actions to ensure their own safety and that of others. The first step is to isolate and de-energize the vehicle by following established protocols. This involves cutting off the main power supply and ensuring all electrical systems are completely shut down, similar to procedures in a tire services or auto collision center for high-risk vehicles.

De-energy procedures should be carried out with precision, especially considering the high voltage batteries used in Tesla vehicles. This may include step-by-step processes like grounding the vehicle, discharging residual energy, and using specialized equipment to safely manage and contain any potential hazards. Proper training ensures technicians can respond effectively during emergencies, minimizing risks associated with high voltage systems, and preparing them to handle situations that might arise in an autobody repairs setting or other critical environments.

Tesla’s high voltage systems, while revolutionary in electric vehicle technology, demand meticulous safety procedures for technicians. By understanding these intricate systems, adhering to stringent safety gear protocols, and mastering emergency response techniques, professionals can confidently navigate potential risks, ensuring both their well-being and the integrity of Tesla vehicles. Embracing comprehensive high voltage safety practices is paramount for fostering a secure working environment and maintaining the cutting-edge standards expected from Tesla and its technicians.