Tesla's high-voltage systems pose significant risks if not handled correctly. Auto collision centers must provide specialized training and equipment for technicians working on Tesla models, focusing on electrical hazards like electrocution and fire risks from battery packs. This ensures paramount Tesla high voltage safety for staff, customers, and vehicle integrity during tasks such as auto detailing or collision repairs, adhering to manufacturer guidelines and regulatory standards. Mechanics play a crucial role in this by understanding EV components, safe disassembly techniques, and proper disposal protocols, fostering a culture of meticulous care and precision in Tesla high voltage safety.

Tesla vehicles are redefining the automotive industry, integrating advanced electric powertrains that demand meticulous care during collision repairs. This article delves into the critical aspect of Tesla high voltage safety in repair centers, exploring the intricate systems and associated risks. We examine best practices and training mechanisms to safeguard mechanics and ensure the integrity of these complex vehicles. Understanding and adhering to safety protocols are paramount for collision repair professionals to effectively service Tesla’s high-tech vehicles.

- Understanding Tesla's High Voltage Systems: A Deep Dive into Components and Risks

- The Vital Role of Safety Protocols in Collision Repair for Tesla Vehicles

- Best Practices and Training for Mechanics: Ensuring Safe Handling of High Voltage Systems

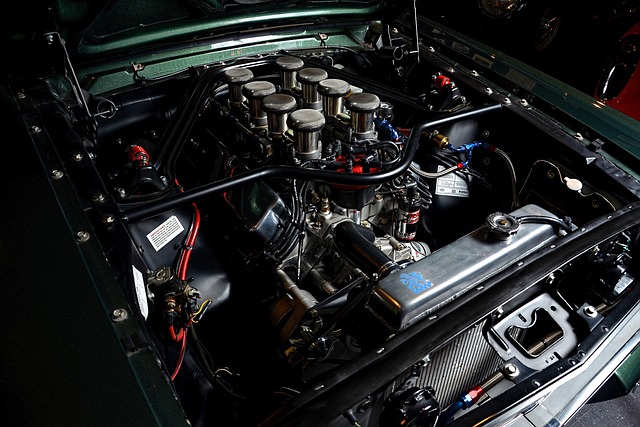

Understanding Tesla's High Voltage Systems: A Deep Dive into Components and Risks

Tesla’s high voltage systems are a complex network of components designed to power their electric vehicles. These include battery packs, motor controllers, and various sensors that work in harmony to deliver efficient and sustainable propulsion. However, understanding the risks associated with these systems is paramount for safety in auto collision centers. A wrong touch or inadequate knowledge can lead to severe consequences due to the high voltage present in Tesla’s vehicles.

Auto collision centers dealing with Tesla models require specialized training and equipment to handle such intricate systems safely. This involves not just physical damage assessment during a car dent repair or paint job but also understanding potential electrical hazards. For instance, battery packs, if not handled correctly, can cause electrocution or spark fires. Thus, ensuring Tesla high voltage safety becomes crucial for the well-being of both technicians and customers in these centers, especially when undertaking tasks like auto detailing or collision repairs.

The Vital Role of Safety Protocols in Collision Repair for Tesla Vehicles

In the realm of collision repair, especially when it comes to Tesla vehicles with their advanced electric propulsion systems, Tesla high voltage safety is paramount. These cars house high-voltage batteries that power their motors, and any collision can pose significant risks if not handled correctly. Safety protocols specific to Tesla high voltage safety are crucial to protect both technicians and the integrity of the vehicle. Such protocols encompass specialized training in handling damaged battery packs, understanding the unique hazards associated with electric vehicles, and implementing rigorous safety checks throughout the repair process.

Adhering to these protocols ensures a safer environment for everyone involved and safeguards the structural integrity of the automotive body shop. Moreover, proper Tesla high voltage safety procedures are essential for achieving flawless auto detailing and auto body restoration, ensuring that the vehicle not only looks as good as new but also functions safely on the road.

Best Practices and Training for Mechanics: Ensuring Safe Handling of High Voltage Systems

In the realm of Tesla high voltage safety, best practices for mechanics are paramount to ensure the integrity and security of electric vehicle (EV) repairs. Mechanics working on Tesla vehicles, especially those with high voltage systems, require specialized training in auto body shop settings. This training should encompass comprehensive understanding of EV components, disassembly procedures, and safe disposal protocols for batteries and associated parts. It’s not just about learning to handle high-voltage cables; it involves mastering techniques for mitigating risks during auto body work on these advanced vehicles.

Proper handling of Tesla’s high voltage systems starts with donning appropriate personal protective equipment (PPE). Mechanics should also utilize tools designed for EV repair, ensuring they fit seamlessly with the vehicle’s architecture. Moreover, strict adherence to manufacturer guidelines and regulatory standards is crucial. Regular practice sessions can reinforce these safety measures, making auto body shops more equipped to handle Tesla high voltage safety effectively, thereby fostering a culture of meticulous care and precision in car body repair.

In light of the above discussions, it’s clear that Tesla high voltage safety is paramount in collision repair centers. Understanding the intricate components and potential risks of Tesla’s high-voltage systems is the first step towards ensuring safe and effective repairs. By implementing robust safety protocols, providing comprehensive training for mechanics, and adhering to best practices, collision repair centers can effectively navigate the challenges posed by these advanced electric vehicle systems. This approach not only safeguards technicians but also ensures the integrity and performance of Tesla vehicles post-repair.